WE BUILD AMAZING MACHINES FROM SCRATCH THAT TRANSFORM A COMPANY'S ABILITY TO MEET THE NEEDS OF THEIR CUSTOMERS AND THE MARKET

Abacus is the one stop automation company

Speed

Motion & Timing Efficiency

Precision

reliable accuracy for production control

Profitability

Return on Investment for long & short term

Process Driven Design

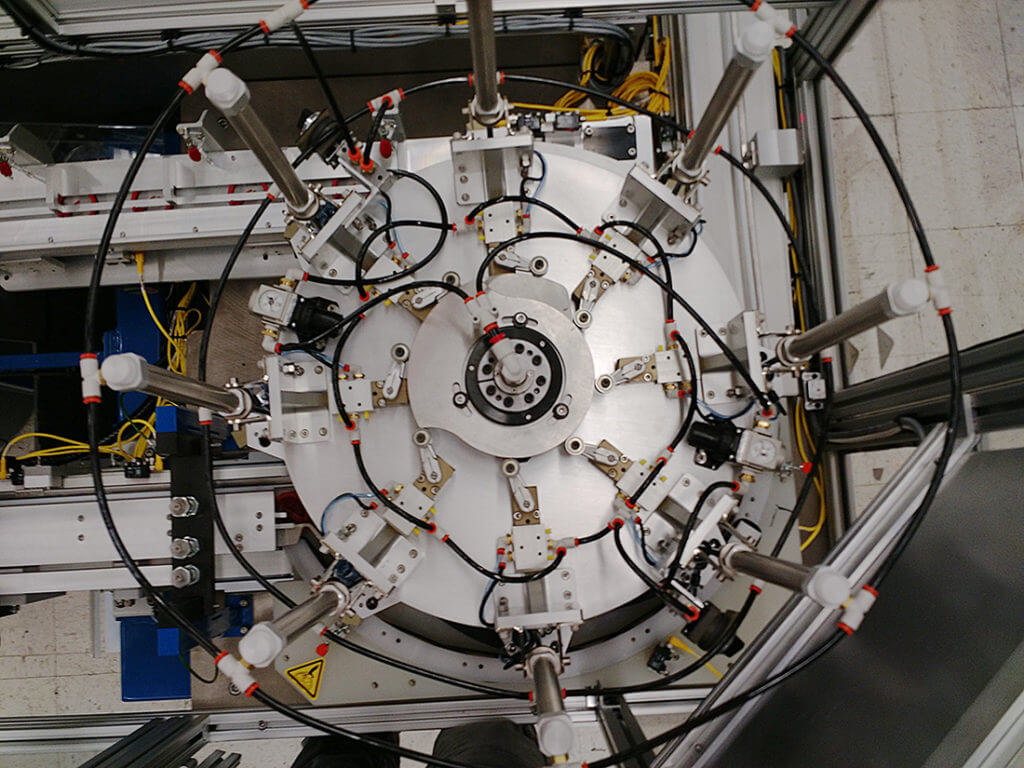

Part Handling and Assembly

Maximize throughput, remove human error through high repeatability, and eliminate ergonomic issues through the use of automated handling and assembly systems for your product. We will work with you to determine the best method and process flow for producing your products – from bulk infeed of a particular part all the way to complex mechanical coupling multiple components.

Photo: Multi-Component Indexing Assembly Dial

Highly Adaptable Flexible Automation

We specialize in custom solutions to our customer’s unique problems. Our many years of building “turn-key” solutions have exposed us to a wide variety of challenges and have provided us with a broad base of technical experience that we would be pleased to apply to your project.

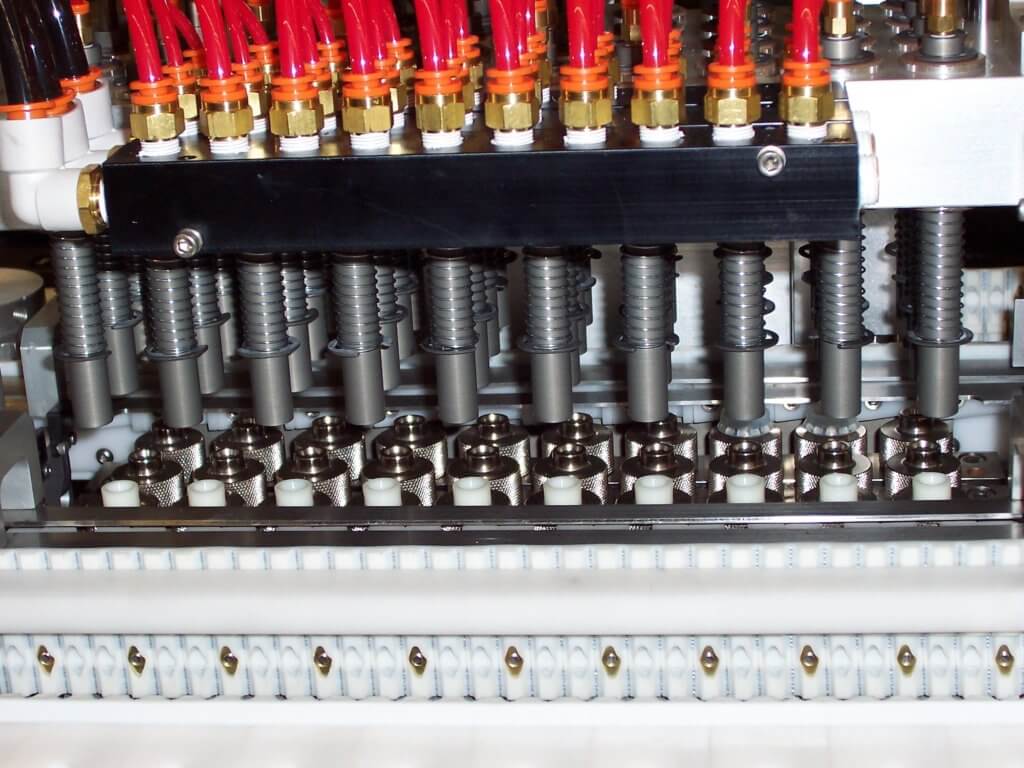

Photo: Fluid Dispensing End Of Arm Effector

Production Quality Control

Our equipment incorporates multiple features to ensure a quality product, reliably & repeatably. Every motion is sensed, every critical process is measured, and every operation sequence is optimized to achieve the best output of product at efficient rates.

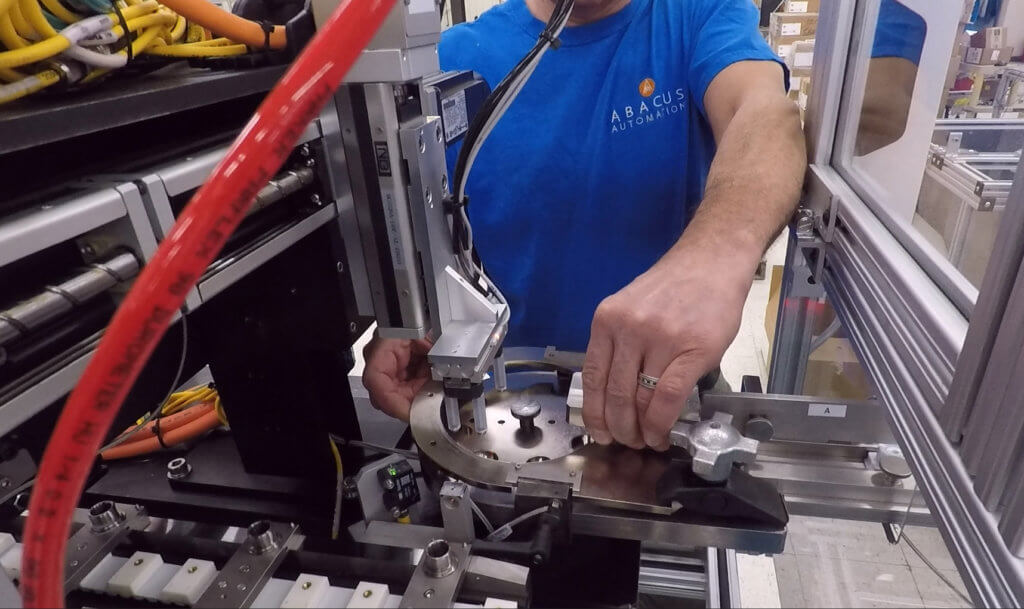

Photo: Mullti-Unit Leak Testing Station

Fast Product Changeover

Quickly switch between different styles of product – and back again. Our Fast-Change-Over systems allows a more Flexible Automation permitting multiple products to run on one production line, offers quick or even push-button changeover and can be easily re-programmed and tooled for new products and future expansion

Photo: Easy Indexing Dial Changeover

Efficient Conveying and Palletizing

Keep your production running to meet customer demand with an automated transfer system or downstream packaging process. Your part’s unique handling requirements can be accommodated by our specifically designed solutions.

Photo: Gantry Palletizing System For Hasboro Play-Doh

Our Customers

The high quality of our machines has strengthened our relationship with our customers – bringing them back to us for new opportunities to work as a team once more and meet their needs in the most cost-efficient way. A few of our customers include:

Our Full Service Development Process Simplifies Custom Builds

We enable your complete control of the entire design and build process. Every step of the engineering problem solving moves seamlessly from each team of specialists. This design and development process has evolved from over 35 years of customized manufacturing problem solving. This ensures that your custom machine is a pre-tested, turn-key success.

- Process Development

- Mechanical Engineering

- Electrical Engineering

- Software Programming

- Drafting, Analysis & Archiving

- Replacement Parts & Supplies

- Full Customer Service

Custom Built Production Automation Solutions

We design and engineer every system for fastest and most efficient production possible. Our process design includes all phases of your growing manufacturing needs.

- Assembly

- Automatic Testing

- Packaging

- Inspection

- Material Handling

- Data Acquisition

Force Monitoring, Check Weighing

Force Monitoring, Check Weighing

Force Monitoring, Check Weighing

Force Monitoring, Check Weighing

Custom System Integrations

- Robot Integration

- Force Monitoring

- Vision Systems

- Fluid Dispensing

- Resistance Welding

- Ultrasonic Welding

- Fastening Systems

- Distance Measurement

- Check Weighing

- Laser Marking & Cutting

- Conveying Systems

- Palletizing Systems